Our Plants

Kawasaki Plant

A metropolitan production center

that responds to high-quality needs in Japan and overseas

Characteristics

The Kawasaki Plant consists of two buildings. One is the Semiconductor Process Gas Building, where semiconductor process gases are produced. The other is the Specialty Gas Building, where JCSS zero gases and very-high-pressure gases are produced.

The plant’s production framework for specialty gases has been reinforced in recent years to respond to the increase in high-level needs for high-quality SiH2Cl2 (dichlorosilane) and COS (carbonyl sulfide) among semiconductor manufacturers in Japan and overseas.

Within the Taiyo Nippon Sanso Group, these two gases are handled only by the Kawasaki Plant.

Main products handled

- Carbonyl sulfide (for etching in silicon processes)

- Dichlorosilane (process gas for silicon semiconductors)

- High-purity gases (zero gases, carrier gases, gases for atmosphere control, etc.)

- Mixture gases (for light bulbs, reduction tests, radiation measurement, etc.)

- Very-high-pressure gases

TOPIC

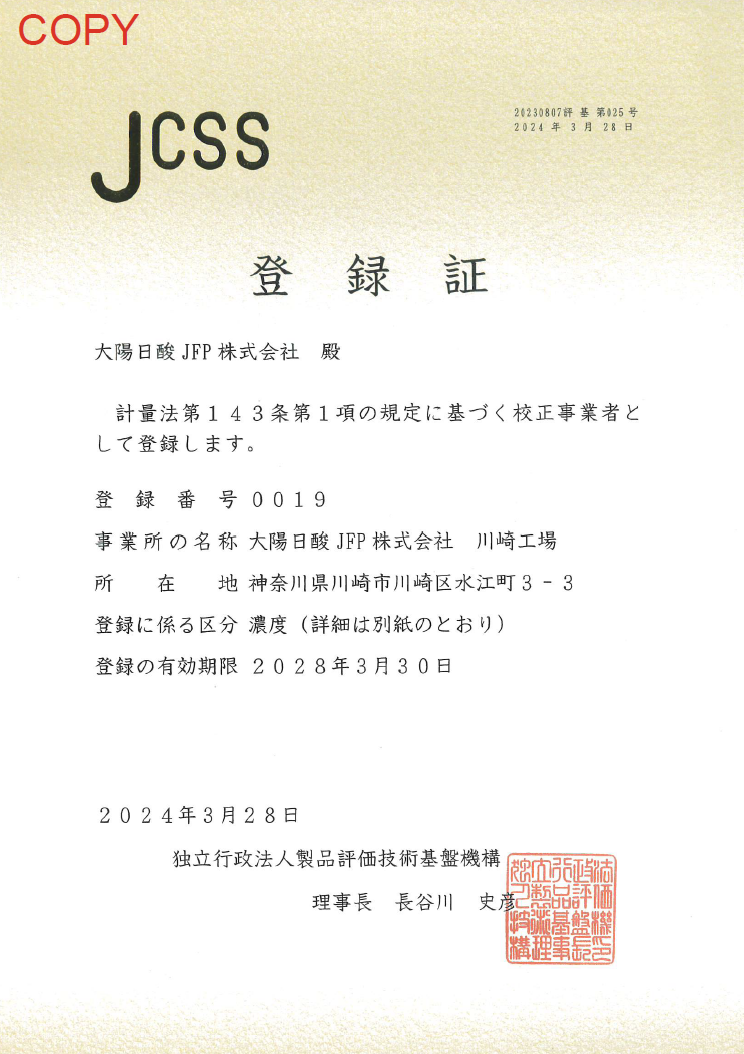

JCSS accredited calibration laboratory for standard gases

The Kawasaki Plant is a standard gas (zero gas) production plant accredited by JCSS. The impurity value of gases is determined based on designated secondary standard gases produced by the Oyama Plant.

GW products (pure gases, standard gases)

The series of products named “GW products” (pure gases, standard gases), which comply with international standards WLTC and WHDC for automobile exhaust gases and fuel regulations, are produced and supplied in collaboration with the Oyama Plant.

Kanagawa Prefecture Award for Meritorious Service in Environmental Conservation and Industrial Safety

The Kawasaki Plant received the Kanagawa Prefecture Award for Meritorious Service in Environmental Conservation and Industrial Safety in July 2017, in recognition of its long years of contribution to the safety of high-pressure gases.Semiconductor Process Gas Building

Largest plant for the production of dichlorosilane and COS in Japan

Receiving raw materials

Filling

Automatic filling equipment

Dichlorosilane and carbonyl sulfide are automatically filled with high precision. The filling process can be remotely operated using a graphic panel.

Analysis

Analysis room

A sophisticated analyzer is installed to analyze raw materials and products for impurities.

Cylinder storage room

Specialty Gas Building

Largest JCSS zero gas production plant in Japan

Cylinder storage room

Cylinder storage room

Cylinders of various high-purity gases are stored here. The Kawasaki Plant produces the largest volume of pure gases among the company’s four plants.

Filling

Filling equipment

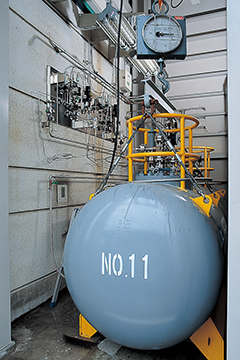

This equipment not only produces high-purity gas products, but also very-high-pressure products (max. 41.2MPa), which are rare even within Japan.

Analysis

Analysis room

High-precision standard gases that are produced in-house are used to conduct advanced raw material acceptance inspection, pure gas impurity analysis and mixture gas composition analysis.