Our Plants

Oyama Plant

A leading plant that produces

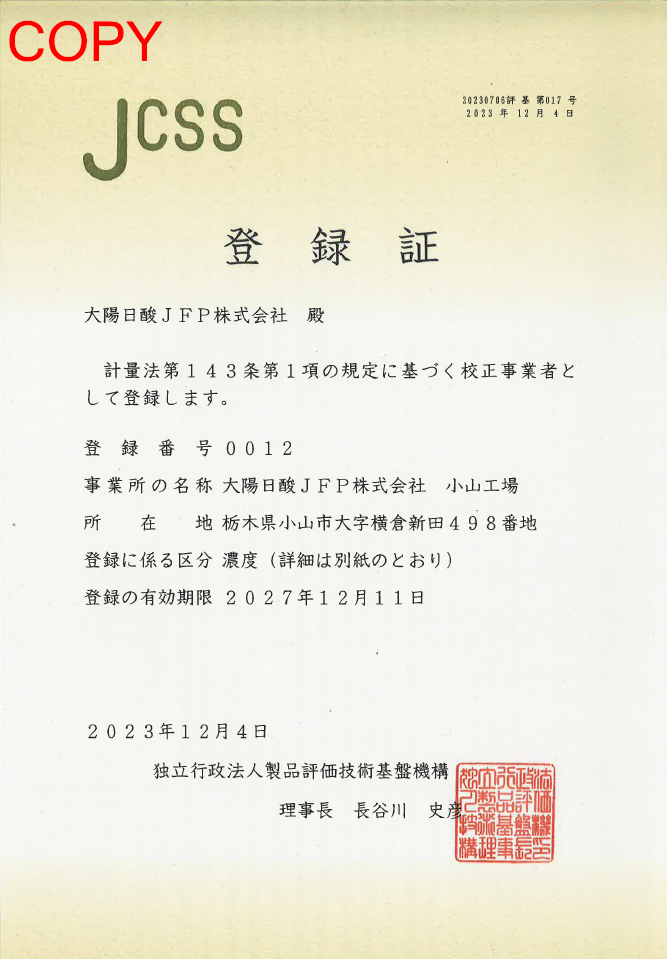

JCSS/MRA certified standard gases

and a variety of specialty gases

JCSS/MRA certified standard gases

and a variety of specialty gases

Characteristics

The Oyama Plant handles high-purity gases, standard gases, semiconductor process gases, and mixture gases as the largest specialty gas plant in Japan.

In particular, it enjoys high acclaim from many industries for its capacity to produce standard gases made to order for air pollution and automobile exhaust gas measurements.

Main products handled

- High-purity gases (zero gases, carrier gases, gases for atmosphere control, etc.)

- Standard gases (for air pollution analysis, automobile exhaust gas analysis, and calibration of analyzers used in the petrochemical and steel industries, etc.)

- Mixture gases (for heat treatment of metals, reduction tests, excimer lasers, etc.)

- Semiconductor process gases (B2H6 mixture gases, SDS products, etc.)

- Other (standard gases in spray cans, etc.)

- Standard gases (for air pollution analysis, automobile exhaust gas analysis, and calibration of analyzers used in the petrochemical and steel industries, etc.)

- Mixture gases (for heat treatment of metals, reduction tests, excimer lasers, etc.)

- Semiconductor process gases (B2H6 mixture gases, SDS products, etc.)

- Other (standard gases in spray cans, etc.)

TOPIC

JCSS/MRA accredited calibration laboratory for standard gases

The Oyama Plant renewed its accreditation as a JCSS/MRA accredited calibration laboratory for standard gases, and acquired MRA certification in December 2019. MRA (mutual recognition agreement) is an agreement among multiple parties to mutually recognize international criteria and standards. The Oyama Plant has passed the screening for this agreement.

GW products (standard gases)

We have recently commenced the production of original standard gases that we have named “GW products.” These products comply with international standards for automobile exhaust gas and fuel regulations, and are widely well received.

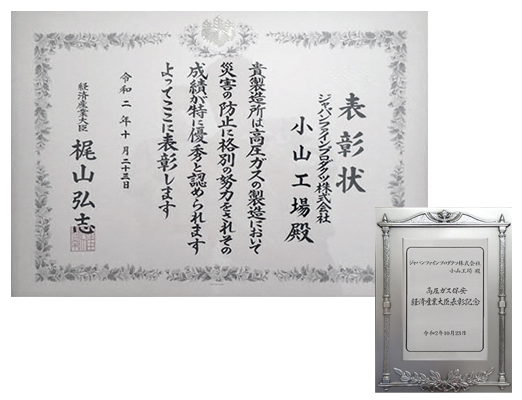

METI Minister’s Award for High-Pressure Gas Safety

The Oyama Plant has received the METI Minister’s Award for High-Pressure Gas Safety in October 2020, in recognition of its long years of contribution to the safety of high-pressure gases. *METI : Ministry of Economy, Trade and IndustryPrinciple facilities at the Oyama Plant

Ultra-precision scale

Reference gases are produced according to the weighing method using an ultra-precision scale. These gases are used to determine the analysis value of standard gases, for the production and supply of products.

Data processing equipment

Human errors are prevented by creating calibration curves and valuating gases using the output from a nondispersive infrared analyzer or other such instrument and sending the valuation result to the production system.

Spray cans

Gases may be delivered in low-pressure spray cans when requested by university laboratories and other such customers who require small amounts of gases that can be used conveniently.

HAPs & TO14 (standard gases for measuring hazardous air pollutants)

High-density analyzer (GC-MS for environmental analysis)

In recent years, global initiatives are being taken to reduce hazardous air pollutants (HAPs). The Oyama Plant plays a large role in these initiatives by producing and supplying standard gases for measuring HAPs.